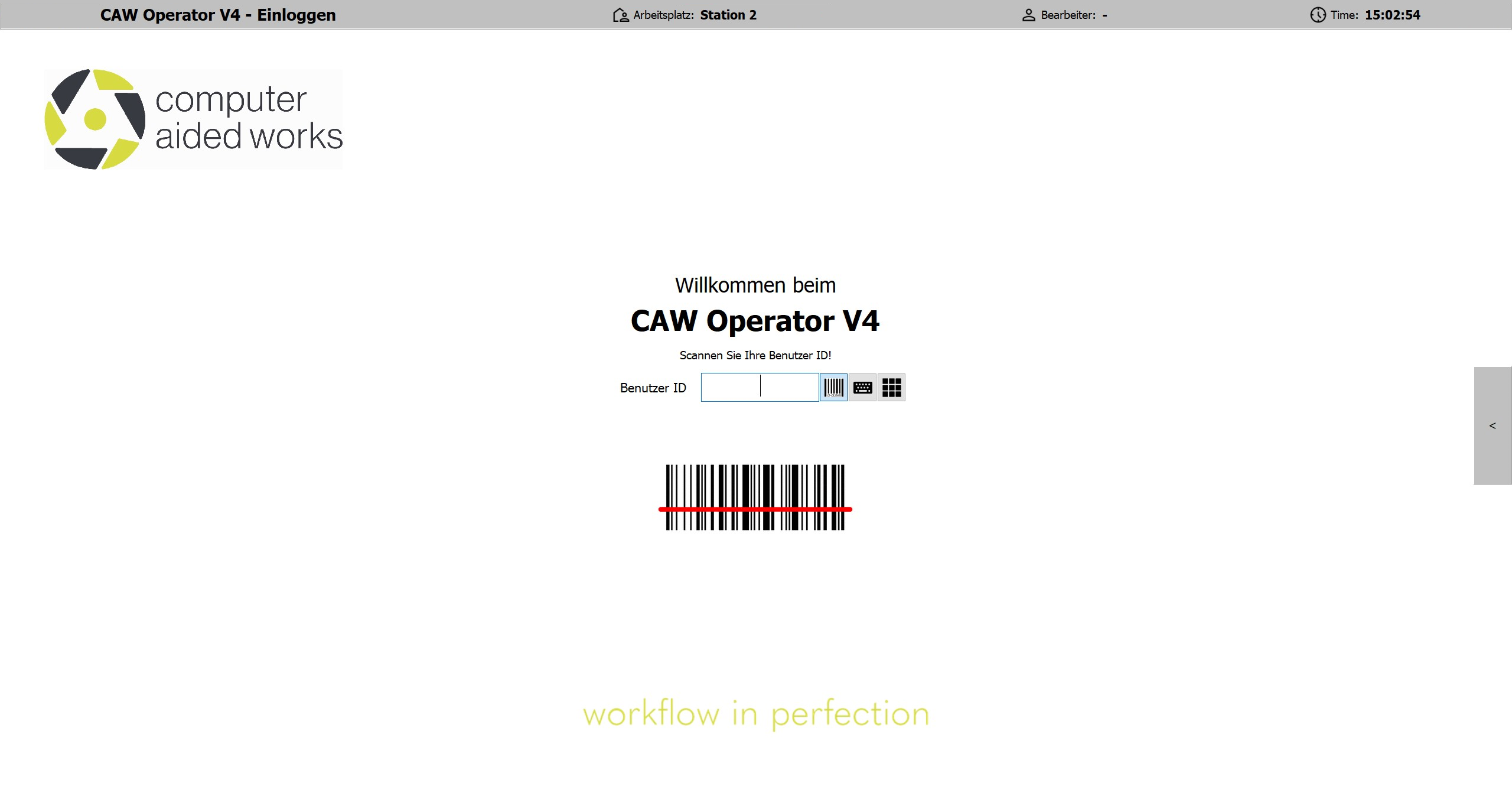

Computer Aided Works im Überblick

Die Einsatzbereiche unserer Werkerführung

Die Autosynchrone Werkerführung® digitalisiert Arbeitsabläufe, sichert die Produktqualität und verbessert die Produktivität. Unser System bietet Assistenz, Qualifizierung und Dokumentation.

- Fokus: Assistenzsystem und Werkerführung

- Mitarbeiterqualifizierung

- Multimediale und standardisierte Dokumentation inkl. Übersetzungen

- Mehrsprachige Arbeits- und Schulungschecklisten

- Fertigung & Montage

- Qualitätssicherung

- Versand

- Mess- und Prüfsysteme

- Kommisionierung

- Automotive / Automobilindustrie

- Kunststoffindustrie

- Maschinen- und Anlagenbau

- Werkzeugbau

- Medizintechnik

- ...und viele Weitere